EV Battery and Energy Storage Tape Solutions

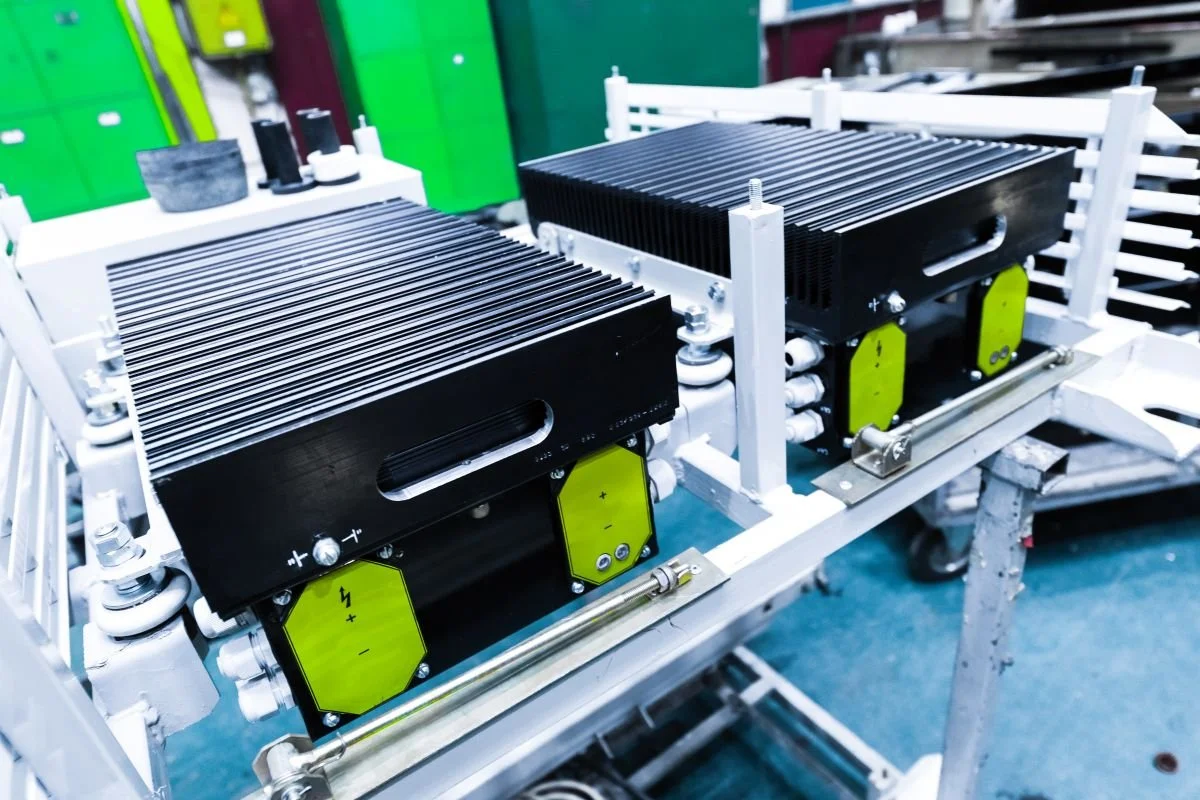

When battery and energy storage systems require thermal and electrical insulation of components, specialty pressure sensitive adhesive (PSA) tapes are the solution engineers choose. These tapes offer industrial strength thermal management, electrical insulation, shock absorption, and prevent fluid intrusion . As electrical insulation and barrier materials, they are ideal for EV battery and ePowertrain systems as well as EV charging infrastructure. are designed to handle demanding environments.

At Engineered Materials, we work with OEMs and system integrators to provide custom-converted PSA tapes tailored to the specific demands of EV battery and energy storage systems.

Our specialty electrical insulation and thermal management materials are selected for dimensional stability, high dielectric strength, and excellent resistance to arc, ignition, and tracking. When combined with our custom converting capacities, this makes sure you get the performance, safety, and compliance you need for your application environment.

Whether you’re looking to improve thermal barriers or enhance electrical insulation, our tapes are easy to convert, cost-effective, and engineered to meet the strict reliability standards of the tech industry.

Custom PSA Tape Solutions for

Electric Vehicle Batteries and Energy Storage Systems

Cell-to-cell thermal runaway propagation

Vent path protection

Sealing against fluid intrusion

EV battery assembly and disassembly

EV battery electrical insulation and connection

Electromagnetic interference protection

Lightweighting and thermal management

Cushioning to protect from shocks and vibration

eMotor assembly and manufacturing

Thermal interface materials for heat sinks

Cold plate insulation

Module housing insulation

Electrical cell barriers

Venting path barriers

Venting hole covers

Equipment mounting and securing

Environmental monitoring

Airflow management

Why Use PSA Tapes for Your EV Battery and Energy Storage Systems?

Improve Performance, Durability, and Aesthetics

High sheer strength and bonding to structural adhesives

High electrical insulation and dialectic strength

Fulfills cleanliness requirements

Peel adhesion on aluminum

Bubble-free application

Can act as gap fillers

Resistance against hot particle burn-through

Thermal and electrical conductivity

High temperature resistance

EMI / RFI Shielding

Shock absorption

Blast resistance

Fire retardant versions

Mechanical reinforcement

Thermal isolation

Low tack for easy positioning

Our Products Meet Federal Regulations and Industry Specifications

UL510A Standard, Category OANZ2, File No. E17385 (1350F, 1351, 1350T, 1388)

CSA certified: Standard C22.2 No. 66, File No. 093411, Class 9052-30

Flame-retardant, UL temperature rated up to 200°C (392°F)

UL 94 V0

UL File E65069

Flame resistant up to 1000°C (1832°F) for at least 10 minutes

Find the Right PSA Tapes for Your Application

3M™ Polyester Film Electrical Tape 1350F-1

3M™ UVi Electrical Insulation Tape 1924B-1

3M™ Polyester Film Electrical Tape 1350F-1

3M™ Polyester Film Electrical Tape 1350F-2

3M™ UVi Electrical Insulation Tape 1924B-1

3M(TM) Polyimide Film Electrical Tape 92

3M™ Flame Barrier FRB-NT

3M™ Torch Flame Resistant Barriers TFRB-SE1 and TFRB-SE3

3M™ Glass Cloth Electrical Tape 9

3M(TM) Thermally Conductive Acrylic Interface Pad 5571

3M(TM) Thermally Conductive Acrylic Interface Pad 5590H

3M(TM) Thermally Conductive Silicone Interface Pad 5583S

Tflex 300 / 300 TG

Avery Dennison FM 2333 Double Coated Tape

Avery Dennison FT 8217 Double-Sided SB Non-Woven Tape

Bisco HT-800 Medium Silicone Foam

Our Process

Material Selection. Custom Fabrication. On-Time Delivery.

Discovery

We ask all the right questions to help you find the solutions to your adhesive issues. On which surfaces will the tape be applied? Is the surface rough, smooth, curved, or irregular? What are the weight requirements? Is the tape permanently placed or will it need to be removable? We take the time to understand the furniture you manufacture and where and how it will be used. Our discovery process is thorough, but we make it easy for you to find exactly what you need.

Material Selection

Choosing the right materials depends on the surfaces being bonded, their texture, and the environment in which the furniture will be used. We stock a wide range of adhesive transfer tapes, VHB (Very High Bonding) tapes, double and single-sided tapes, and many other materials specifically designed for any application. We help you select the right material and adhesive coat weight based on the furniture you manufacture and how the tape needs to be used.

Custom Fabrication

We custom fabricate all our materials to create the perfect fitting part for your furniture, every time. From laminating to slitting, die cutting, kiss cuts, laser and waterjet cutting, and so much more, we have the capabilities and experience to create any custom shape that fits your adhesive needs. Not sure exactly what you need? No worries! Our parts design specialists can help you with product design, prototyping, testing, and implementation of brand-new parts for your furniture!