When to Use Reclosable Hook and Loop Fasteners: Engineering Guide to Product Options, Applications, and Attachment Methods

Reclosable hook and loop fasteners give engineers a flexible, clean, and reusable alternative to hardware in assemblies that require frequent access, serviceability, or simplified installation. While these systems appear simple, choosing the correct construction, adhesive system, and performance grade directly influences long-term durability. This guide expands the fundamental descriptions in your original draft and adds engineering considerations that help ensure proper material selection.

What Are Hook and Loop Fasteners?

Hook and loop fasteners are engineered mechanical systems built around two complementary surfaces, one lined with small, rigid hooks and the other with soft, flexible loops. When pressed together, the hooks engage the loops to create a durable, reusable bond capable of thousands of open and close cycles with minimal performance loss.

Often known by the brand name VELCRO®, these systems are also offered as 3M™ Scotchmate™, or hook and loop tape. Their lightweight construction and repeatable engagement make them a reliable alternative to screws, snaps, and traditional hardware, especially in applications that require frequent access, clean attachment, or simplified assembly.

Common Attachment Methods

Reclosable fasteners are available in multiple constructions designed to match different materials, performance expectations, and manufacturing workflows. Choosing the correct attachment method ensures durability and consistent closure strength over its intended life

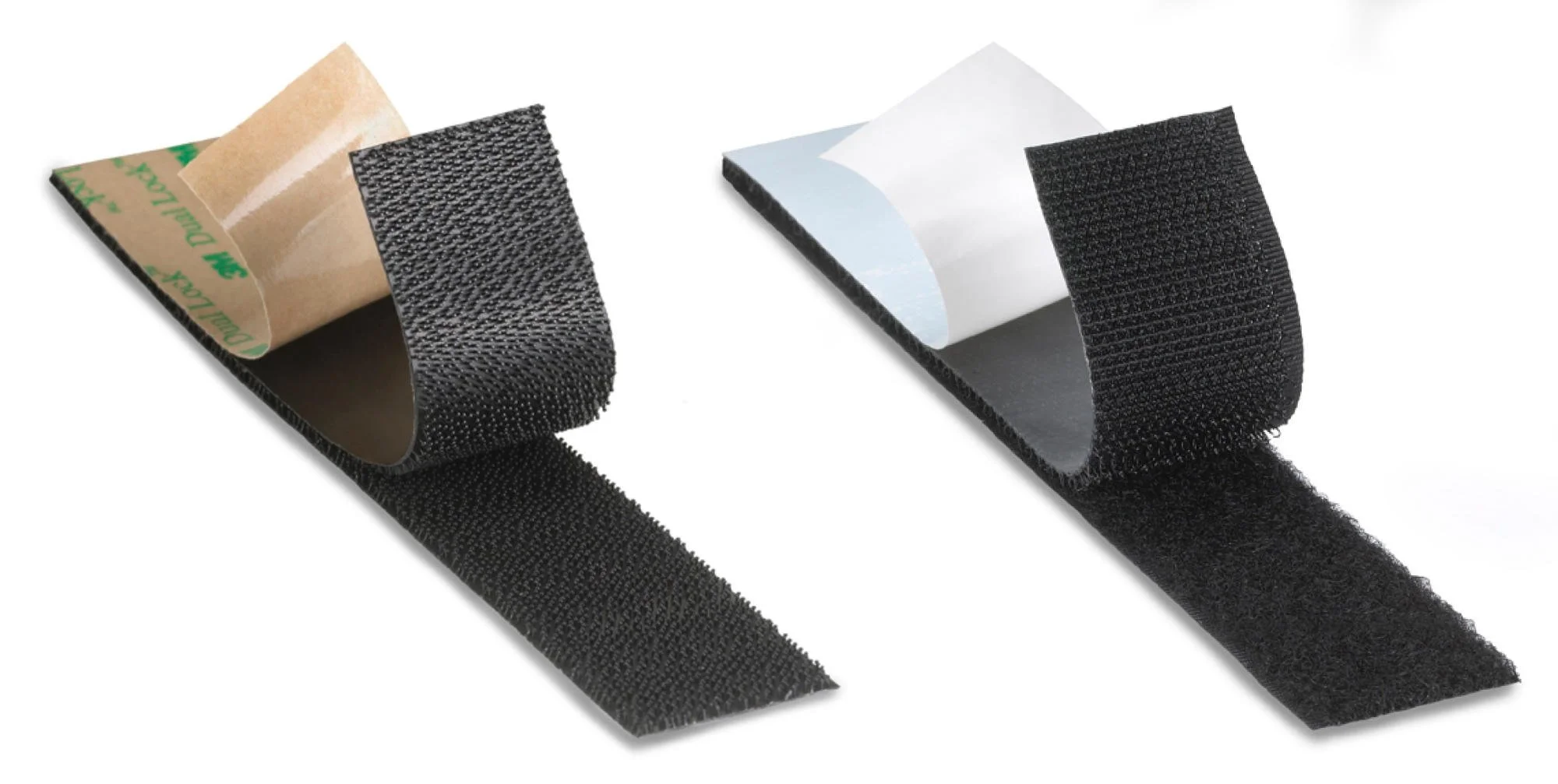

Adhesive Backed Hook and Loop

Adhesive backed reclosable fasteners pair hook or loop material with a pressure sensitive adhesive (PSA) for clean, peel and stick installation on metals, plastics, composites, foams, textiles, and painted surfaces. Systems like VELCRO® and 3M™ Scotchmate™ engage through a hook to loop interlock that creates a secure blind fastening point. A blind fastening point becomes concealed once the two sides are mated, which keeps hardware out of sight and maintains a clean finished appearance.

Key performance characteristics:

1,000–5,000 reclosures depending on construction

Easy peel and stick installation with multiple PSA types available

Light vibration dampening from the compressible hook and loop interface

Fire retardant options meeting FAR 25.853, BMS 8-285, and MIL-A-A-55126C

High temperature acrylic PSA versions up to approximately 200°F

Compatible with custom die cut and slit formats and available without adhesive

Typical PSA choices include rubber PSA (high tack, indoor applications), acrylic PSA (high shear, outdoor durability), and low-surface-energy (LSE) acrylic PSA for polypropylene, polyethylene, and powder-coated surfaces. Acrylic systems also offer significantly better UV, temperature, and humidity resistance than rubber PSAs.

Ideal for:

Signage, banners, tradeshow exhibits, removable seat cushions, acoustic insulation, medical device attachments, and bus, rail, or aircraft interior panels.

Sew-On Hook and Loop

Sew-on constructions use a woven or knitted textile backing designed to be stitched directly into garments, upholstery, medical wearables, tactical gear, or soft goods. Because attachment relies on stitching rather than adhesive, performance remains consistent during flexing, bending, laundering or extensive mechanical cycling.

Technical advantages:

Up to 5,000 open and close cycles

Flame retardant versions meeting FAR 25.853

Military grade materials meeting MIL-A-A-55126C

Aramid high temp options rated up to 350°F

These are common in uniforms, footwear, gear bags, removable seat covers, automotive carpet, and medical straps where flexibility and wash durability are essential.

Double Sided Back-to-Back (VELCRO® ONE-WRAP®)

Back-to-back fasteners, such as VELCRO® ONE-WRAP®, place hook material on one side and loop material on the other so the strap can wrap around an object and fasten to itself.

Best used for:

Cable and wire management

Cinching straps

Adjustable bands

Temporary or frequently modified installations

These systems support about 50 cycles, making them excellent for fast handling and repositioning rather than long term durability.

Reclosable Fastener Brands and Comparisons

VELCRO®

The most widely recognized hook and loop brand, offering options for:

Adhesive backed and sew-on constructions

Low profile systems

Fire retardant and high temperature materials

Military grade products in multiple tactical colors

Used across apparel, soft goods, displays, industrial assemblies, and transportation interiors.

3M™ Scotchmate™

3M’s hook and loop portfolio provides:

Reliable closure strength and dimensional stability

Integration with high performance 3M™ pressure sensitive adhesives

Indoor and outdoor durability

Options meeting FAR 25.853, BMS 8-285, and military specifications

Excellent for plastics, composites, foams, metals, and engineered surfaces.

3M™ Dual Lock™

A high strength reclosable fastener using interlocking mushroom shaped stems rather than traditional hooks and loops. This design increases tensile strength, peel resistance, and vibration stability.

Benefits include:

Up to 5 times the tensile strength of standard hook and loop

Up to approximately 1,000 reclosures

Audible “snap” for closure confirmation

Superior vibration resistance

Multiple stem densities (170, 250, 400)

Available with rubber, acrylic, or LSE acrylic PSA, or plain back

Dual Lock is ideal for interior panels, access doors, electronics housings, architectural panels, and modular enclosures where rigidity and repeatable positive engagement are required.

VELCRO® ONE-WRAP®

A self engaging wrap is used for cable management, bundling, labeling, and reusable straps. Available in standard and FR versions.

Benefits of Hook and Loop Systems

Hook and loop fasteners provide a unique blend of mechanical performance and user friendly design. Key advantages include:

Reusable closures for assemblies requiring frequent access

Tool free installation and disassembly

Lightweight and low profile designs that reduce overall assembly mass

Customizable across color, width, thickness, hook density, loop density, and PSA type

Fire retardant constructions for regulated environments

Multiple adhesive chemistries (rubber, acrylic, FR rubber, LSE acrylic)

Additional Engineering Advantages

Vibration Dampening

The hook and loop interface provides a soft, energy absorbing layer that reduces buzz, rattle, and micro-movement. This is valuable in transportation interiors, acoustic panels, medical housings, and equipment enclosures.

Fire Resistance

These materials are required for aircraft seating, public-transit components, tactical gear, and emergency response equipment. A range of fire retardant hook and loop options meet stringent industry requirements, including:

FAR 25.853 for aircraft interiors

BMS 8-285 for aerospace materials

MIL-A-A-55126C for military textiles

These materials are essential in aerospace seating, public transit applications, tactical gear, and emergency response equipment.

Open and Close Cycle Life: A Practical Comparison

Different fastener constructions support various levels of reusability, and choosing the right type ensures long term reliability.

Standard hook and loop deliver the highest cycle life, with most constructions supporting 1,000 to 5,000 cycles before engagement strength gradually decreases. These versions excel in removable insulation panels, textile components, and light mechanical attachments requiring repeated access.

Low profile hook and loop systems offer a slimmer, lighter construction that still delivers reliable performance for 1,000 to 3,000 cycles. By reducing overall thickness, these materials fit tight spaces and improve comfort in wearables, medical straps, and compact device assemblies.

Back-to-back (ONE-WRAP®) styles offer about 50 cycles, optimized for quick adjustments and cable management rather than high durability fastening.

3M™ DUAL LOCK™ provides up to 1,000 cycles with significantly greater tensile strength and exceptional vibration resistance. It is the best choice when stronger, more rigid closure is required but tool free operation is still desired.

Industrial and Technical Applications

1. Electronics and Wire Management

Bundling and routing cables

Removable access panels

Adjustable harness or wire routing paths

2. Displays and Signage

Repositionable signage

Exhibit booth panels

Seasonal and temporary branding

3. Medical Devices and Wearables

Adjustable straps

Reusable diagnostic harnesses

Soft attachment points for patient comfort

4. Transportation and Aerospace

Lightweight interior panel fastening

Removable linings and insulation layers

Components requiring frequent service access

5. Apparel and Textiles

Adjustable garment closures

Uniforms and tactical gear

Sew-on or adhesive backed options depending on fabric

Die Cutting: Precision Parts for Faster Assembly

Die cutting converts rolls of hook and loop materials into precision shaped components that speed assembly and improve dimensional consistency. EMI produces:

Custom cut rectangles, squares or circles

Individual die cut parts

Kiss cut parts on pads or rolls

Tabbed liner designs

Custom geometries for mounting, alignment, sealing, or vibration control

This ensures repeatable performance, faster installation, and reduced operator labor.

Slitting and Spooling: Custom Widths That Improve Production Flow

Slitting cuts wide master rolls of hook and loop into precise, narrow widths using razor, shear, or crush cut methods. This produces clean, consistent edges that reduce manual trimming, improve placement accuracy, and minimize material waste. Those slit widths can then be spooled into long, level wound rolls, often thousands of continuous feet, to support steady feed rates, fewer changeovers, and smoother automated or manual assembly.

EMI offers:

Custom narrow widths for sew-on and PSA-backed hook and loop

Level wound spools for long, uninterrupted production cycles

Perforated or sheeted formats for controlled dispensing

High speed slitting specifically optimized for hook and loop materials

Engineered Materials: Your Partner for Custom Reclosable Fastener Solutions

At Engineered Materials, we provide hook and loop tapes, 3M Dual Lock fasteners, and precision-converted components engineered for demanding industrial environments. We help evaluate substrate types, surface energies, environmental exposures, and load conditions to match the right construction and PSA system. Our die cutting, slitting, laminating, and prototyping capabilities produce application-ready parts that integrate smoothly into your manufacturing workflow.

Contact Engineered Materials to review your application. Our team will help you select the correct reclosable fastener solution, improve assembly efficiency, and ensure long-term durability.